Across the Group, growth and sustainability go hand in hand. Reducing the weight of packaging, lowering our carbon footprint, increasing the share of recycled glass or rethinking our products from the design stage: these are all concrete actions that reflect a profound transformation of our model. We are driving this change with our entire value chain — starting with our increasingly committed customers — and helping to build virtuous ecosystems throughout the glass industry.

Acting across the entire value chain

Together with our customers, suppliers, industrial partners, start-ups, reuse networks and collective initiatives, we develop sustainable, practical and scalable solutions. At every stage of the value chain, cooperation makes the difference.

Being a strong link in our ecosystem

Since 2016, our “Glass Schools” have enabled customers and partners to explore the full life cycle of glass, from manufacturing to second life. In 2024, a session at Bout’ à Bout’ was added, reflecting our commitment to reuse.

Moreover, 90% of our suppliers are committed through our Responsible Purchasing Charter, with a target to maintain this level by 2030.

Glass, naturally circular

100% recyclable and infinitely reusable without loss of quality, glass is a model material for circularity. By focusing on reuse and recycling, we are embedding it firmly in the circular economy loop.

To make this ambition a reality, Verallia acts at multiple levels of the value chain, developing both local and industrial solutions. For example, in France, a partnership with Hennessy and Veolia enables local recycling of extra-white glass rejects from spirits bottling.

The eco-design reflex

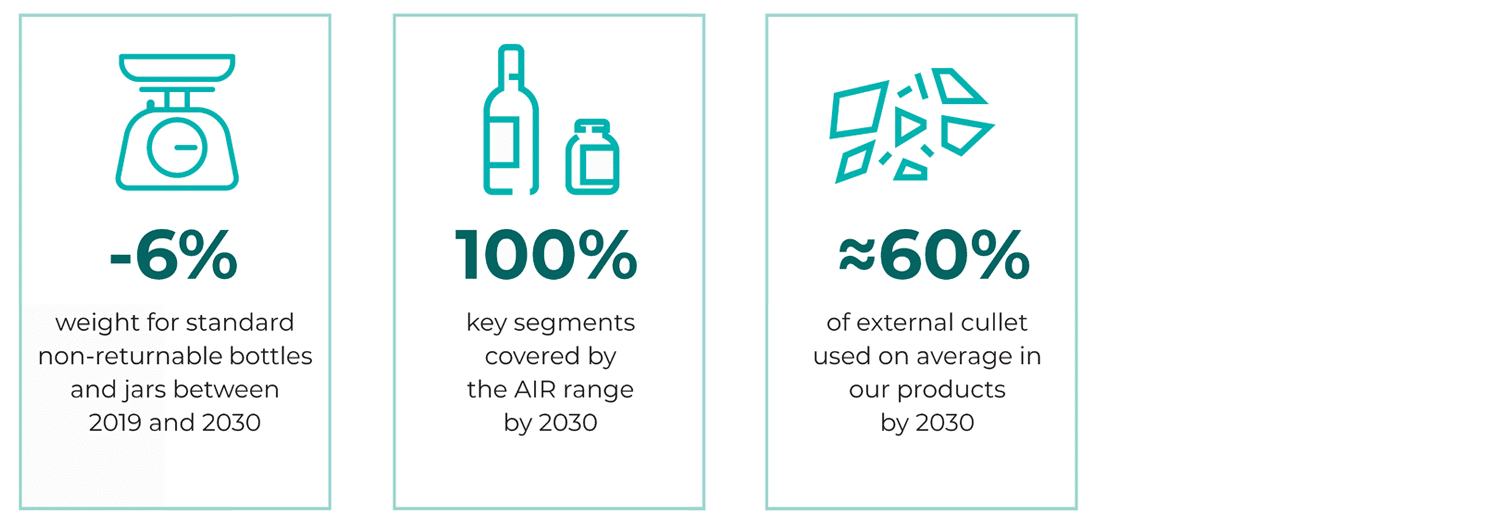

At Verallia, eco-design means making the right choices from the outset. We design packaging that incorporates more cullet, is lighter, or intended for reuse, to minimize its carbon footprint throughout its life cycle.

This approach is based on the 3R rule: Reduce, Reuse, Recycle — and translates into large-scale action.

Lightweighting as a driver of transformation

Reducing the weight of glass packaging is a powerful lever for lowering its carbon footprint. Verallia is innovating in eco-design to offer lighter, high-performance and sustainable solutions.

- In 2023, Verallia launched the Bordelaise Air 300G, a lightweight version of the classic Bordeaux bottle. In 2024, the range expanded with seven ultra-light food jars featuring optimized design and a versatile “My Air” format, suitable for both alcoholic and non-alcoholic beverages in single-serve portions.

- In Spain, we developed the lightest Cava bottle on the market at 775 g, 125 g less than the traditional model.

- Finally, a proprietary modeling tool helps our customers compare emissions across different eco-design scenarios, based on packaging weight and color.

A shared approach with our customers and partners

Cooperation with our customers and partners ̶ start-ups, manufacturers, local authorities, etc. ̶ enables us to develop practical, reproducible solutions that will accelerate the industry’s transition towards increasingly sustainable glass processes and packaging.

- With PUGET, we designed a “feuille morte” bottle containing 86% recycled glass.

- With Champagne Telmont (Rémy Cointreau), we developed the lightest champagne bottle on the market, in green glass, with 87% recycled content.