Reducing our environmental impact is not a promise — it’s a trajectory. We have decided to act without delay. Decarbonisation, energy transition, water efficiency, preserving natural resources… On all these fronts, our sites are mobilised, our technologies are evolving and our teams are taking action. This translates into next-generation furnaces, intensified efforts to reduce water consumption, the use of cleaner energy sources, and continuous attention to air quality, waste management, and land preservation.

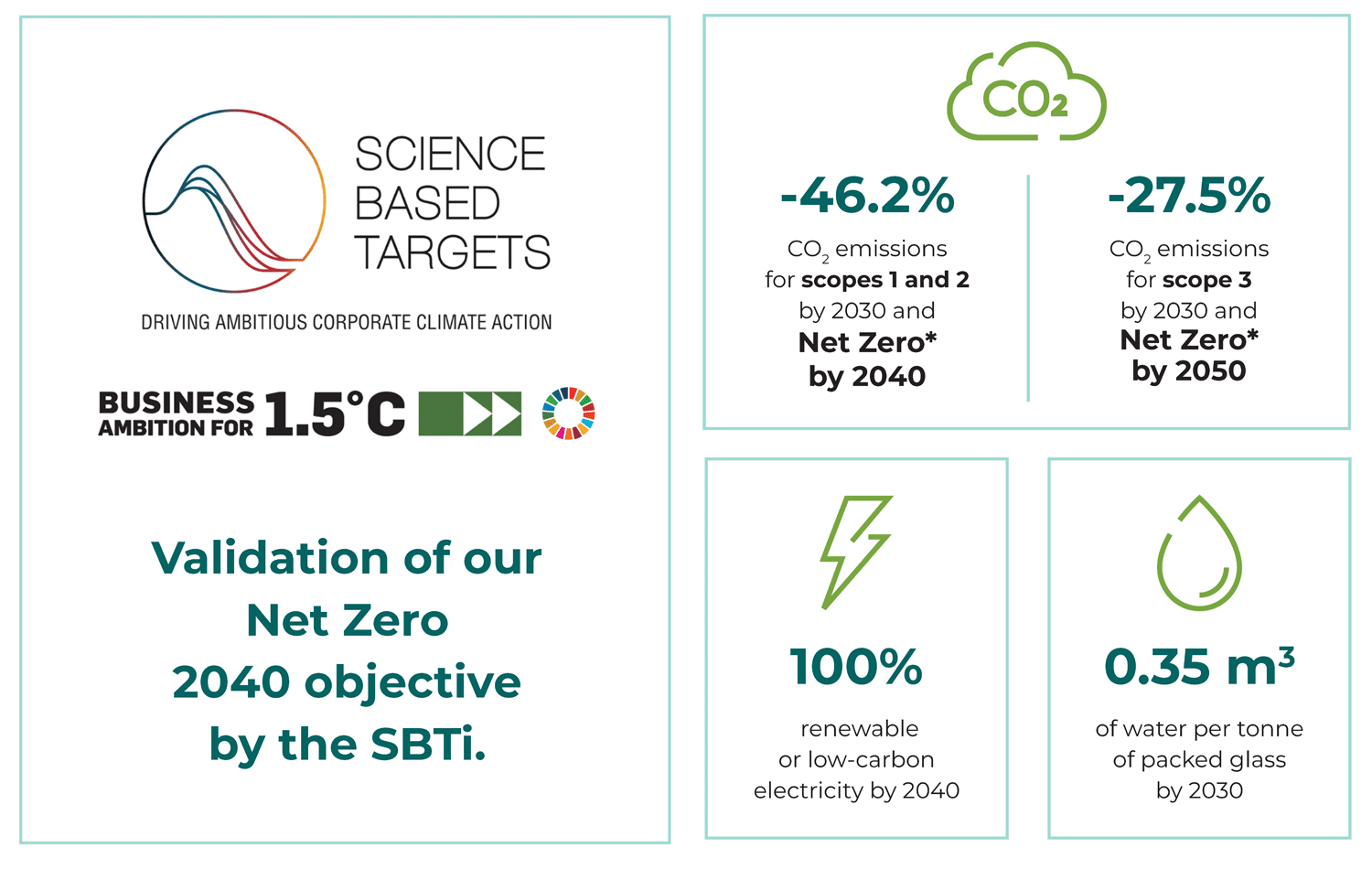

Verallia’s Net Zero trajectory, validated by the SBTi, commits the Group to reducing CO₂ emissions by 90% for scopes 1 and 2 by 2040, with 10% offsetting. For scope 3, the target is a 90% reduction by 2050.

To reduce its CO₂ emissions for scopes 1 and 2, Verallia is focusing on three key levers:

- Using low-carbon raw materials

- Improving energy efficiency through electrification

- Increasing the share of renewable or low-carbon energy

To reduce scope 3 emissions, Verallia works with its suppliers across four levers:

- Raw materials: switching to local sourcing, alternative transportation and sharing the decarbonisation roadmap with the highest-emitting suppliers

- Energy: prioritising low-carbon sources

- Transport: reducing distances, using biofuels or liquefied gas, and developing multimodal transport

- Packaging: developing eco-design, reuse and recycling of pallets, plastic dividers and films

The electric furnace in Cognac: a world first for the glass industry

In March 2024, Verallia commissioned the very first 100% electric furnace dedicated to the production of food-grade glass packaging at its Cognac site in France. A world first. This major technological step forward reduces CO₂ emissions by 60% compared with a traditional furnace. One year after commissioning, the results are clear: team autonomy, customer satisfaction, and fully decarbonised production for some clients.

Decarbonising melting, step by step

Glass melting is the main source of direct emissions for the Group. Verallia is acting on two complementary levers: progressive electrification of its furnaces and optimisation of its energy mix by increasing the share of low-carbon energy.

Towards a new generation of glass furnaces

Verallia is deploying several furnace technologies:

- Super-boosted: electricity share increased from 7% to around 25%, reducing natural gas consumption and CO₂ emissions; already in place at Chalon-sur-Saône

- Hybrid: powered by 70% renewable or low-carbon electricity and 30% gas; reduces CO₂ emissions by 50%; first deployments in Zaragoza (2025) and Saint-Romain-le-Puy (2026)

- 100% electric: operates solely on renewable or low-carbon electricity; reduces CO₂ emissions by 60%; in operation at Cognac since March 2024

- Oxycombustion: oxygen injection reduces energy consumption and CO₂ emissions by an additional 10%; deployed in Campo Bom (Brazil) and Pescia (Italy)

Towards a greener energy mix

In 2024, Verallia reached 64% renewable or low-carbon electricity, exceeding its 2025 target. The Group aims for 100% by 2040. Photovoltaic panels have been installed on several sites, covering up to 25% of electricity needs.

Alternatives to natural gas are also being explored:

- Biofuels: already used in Zaragoza and Vauxrot

- Syngas: pilot project in Cognac with Charwood Energy

- Hydrogen: industrial project in Essen (Germany), using gas with 60% hydrogen, enabling a 10% reduction in emissions

Reducing our impact on natural resources

Water: an essential resource

Water is mainly used for cooling glass and equipment. Most Verallia plants already operate in semi-closed loops, allowing water to be treated, recycled and reused, limiting withdrawals and losses.

In 2024, nine of our 35 plants are located in water-stressed areas. These sites aim to reduce consumption to 0.25 m³ per tonne of packed glass by 2030, compared to 0.35 m³ for other sites.

Water Cards are deployed in each plant to monitor consumption twice a year and plan concrete actions and investments.

Verallia is also investing in adiabatic cooling towers, which cool water using ambient air without evaporation. These systems reduce water consumption by 40 to 50% and are now systematically installed with each furnace upgrade.

Acting on air and waste

In 2024, only four minor exceedances of SOx and NOx thresholds were recorded and immediately addressed. 58% of the 242,176 tonnes of waste generated were recycled.

Environmental Gemba Tours help map waste flows and identify improvement levers.