Reducing our environmental impact is not a promise — it’s a trajectory. We have decided to act without delay. Decarbonisation, energy transition, water efficiency, preserving natural resources… On all these fronts, our sites are mobilised, our technologies are evolving and our teams are taking action. This translates into next-generation furnaces, intensified efforts to reduce water consumption, the use of cleaner energy sources, and continuous attention to air quality, waste management, and land preservation.

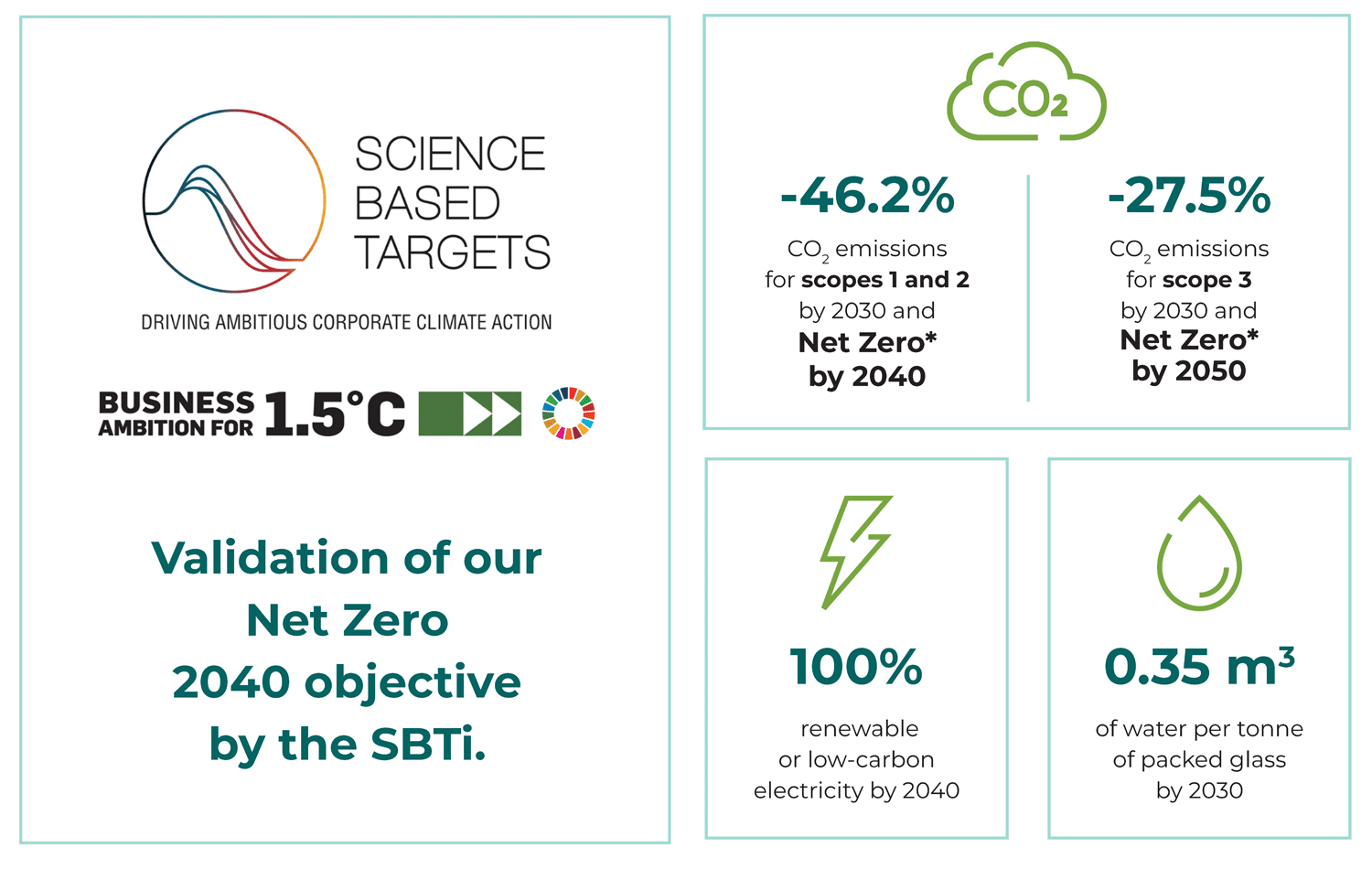

Verallia is the first glass packaging manufacturer committed to a Net Zero target by 2040

Verallia’s Net Zero trajectory, validated by the SBTi, commits the Group to reducing CO₂ emissions by 90% for scopes 1 and 2 by 2040, with 10% offsetting. For scope 3, the target is a 90% reduction by 2050.

To reduce its CO₂ emissions for scopes 1 and 2, Verallia is focusing on three key levers:

- Using low-carbon raw materials, such as cullet.

- Improving energy efficiency through electrification.

- Increasing the share of renewable or low-carbon energy.

To reduce scope 3 emissions, Verallia works with its suppliers across four levers: raw materials, energy, transport and packaging.

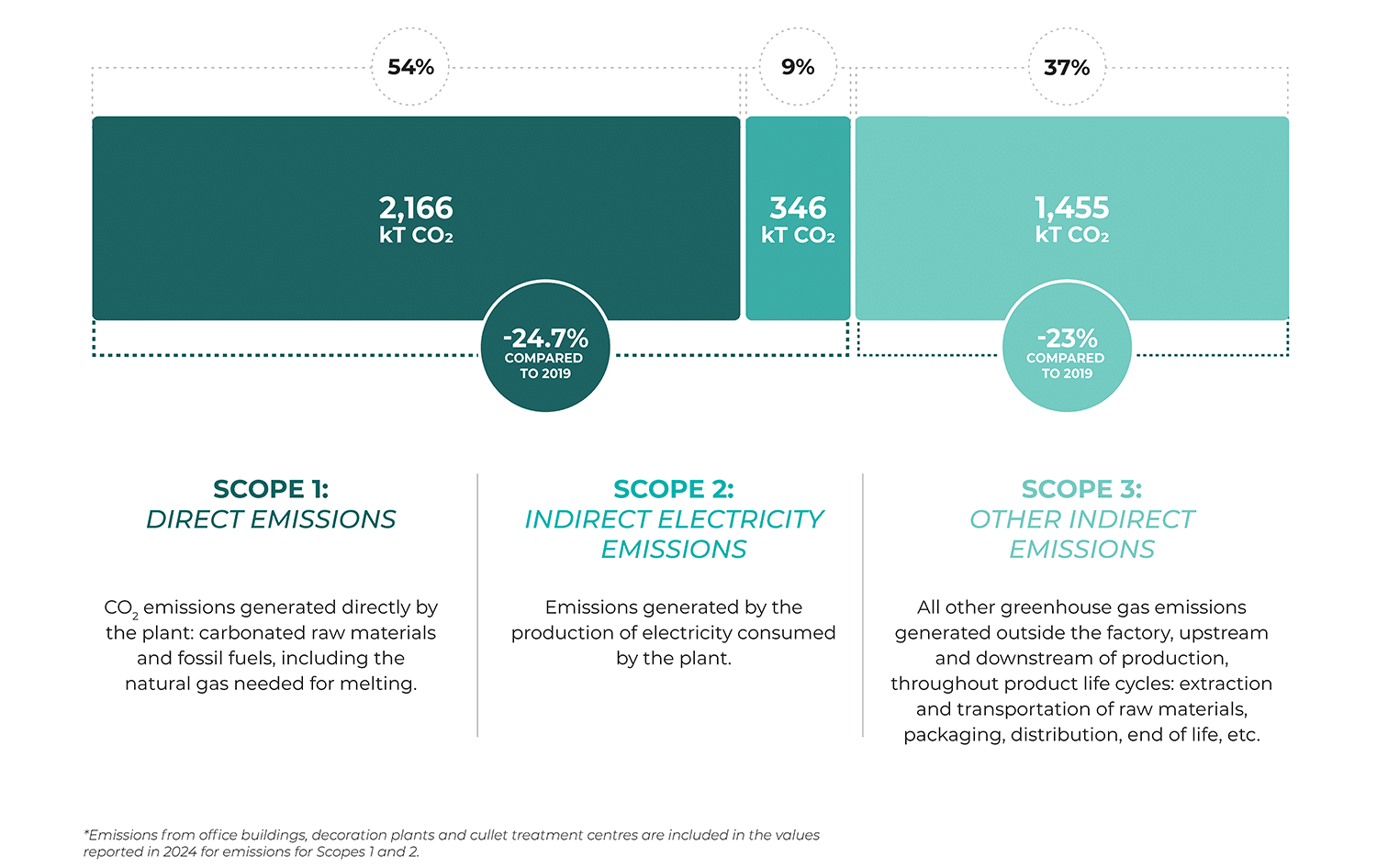

Our 2024 carbon footprint

The electric furnace in Cognac: a world first for the glass industry

In March 2024, Verallia commissioned the very first 100% electric furnace dedicated to the production of food-grade glass packaging at its Cognac site in France. A world first. This major technological step forward reduces CO₂ emissions by 60% compared with a traditional furnace. One year after commissioning, the results are clear: team autonomy, customer satisfaction, and fully decarbonised production for some clients.

Reducing our impact on natural resources

Water: an essential resource

Water is mainly used for cooling glass and equipment. Most Verallia plants already operate in semi-closed loops, allowing water to be treated, recycled and reused, limiting withdrawals and losses.

In 2024, nine of our 35 plants are located in water-stressed areas. These sites aim to reduce consumption to 0.25 m³ per tonne of packed glass by 2030, compared to 0.35 m³ for other sites.

Verallia is also investing in adiabatic cooling towers, which cool water using ambient air without evaporation. These systems reduce water consumption by 40 to 50% and are now systematically installed with each furnace upgrade.